| Quantity: | |

|---|---|

1、Features:

Under the same evaporation conditions, the larger the coating thicknessδ, the smaller square resistance (Ω/□) , the smaller the resistance R, the greater the load current, while the worse self healing properties.

Al/Zn metallized film use heavy edge evaporation method, greatly reduce the contact resistance between the spraying area and the cores of the film capacitors, which has improved the quality of the capacitors.

Al/Zn metallized film has a better pressure resistance.

Al/Zn metallized film has a worse moisture resistance, easily oxidized.

2、Types of Metallized Layer:

Margin size(mm):1.0±0.5、1.5±0.5、2.0±0.5、2.5±0.5、3.0±0.5、4.0±0.5、5.0±0.5

Coating square resistance(Ω/□):Heavy-edge area:(3 ~ 5) ±1;Non heavy-edge area:(5 ~ 65) gradient

3、Cores:

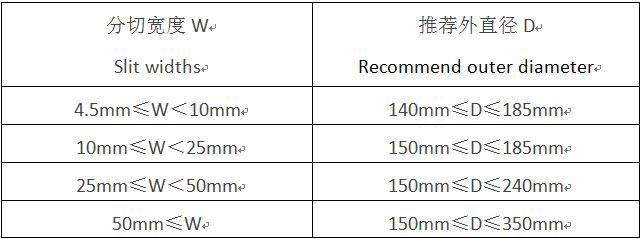

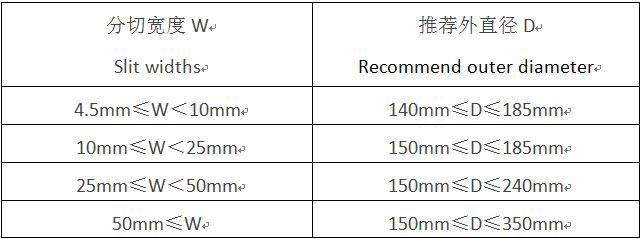

4、 Roll Outer Diameter:

| 性能 Properties | 单位 Unit | 要求 Requirements |

| 密度Density | g/cm3 | 0.905±0.005 |

| 厚度 Thickness | µm | 3.8 ~ 15 |

| 抗拉强度 Tensile Strength | 纵向MD (MPa) | ≥100 |

| 断裂伸长率 Elongation at Break | 纵向MD (%) | 40 ~ 200 |

| 热收缩率 Heat Shrinkage | 纵向MD (%) | ≤5 ( 120°C, 10min) ( 120°C , 10 min ) |

| 介电强度 Break-dowm voltage | V/µm | ≥350 ( 23°C, DC ) |

| 介电损耗因数 Dissipation Factor | - | ≤4×10-4 (20℃,1KHz ) |

| RC值 | ΩF | ≥5×104 |

6、Packing:

7、 Storge:

1、Metallized film should be stored in its original package until its use with temperature 5 ~35℃and humidity less than 85%RH.

2、Metallized layer is easily oxidized when exposure to moisture. Therefore, the film should be used as soon as possible when opened.

3、The recommended temperature is 15 -25℃with humidity less than 60%RH after the package is open.

4、With original sealed package, and stored in the above mentioned conditions, the storage time can be as following:

Al metalized Film: 12 months from the delivered date

Al/Zn Alloy metalized Film: As Zn is relatively unstable, preservation period depends on the resistance of the film:

Less than 10 Ohms: 6 months (from delivery date)

10 Ohms to 15 Ohms: 3 months (from delivery date)

15 Ohms: 1months (from delivery date)

1、Features:

Under the same evaporation conditions, the larger the coating thicknessδ, the smaller square resistance (Ω/□) , the smaller the resistance R, the greater the load current, while the worse self healing properties.

Al/Zn metallized film use heavy edge evaporation method, greatly reduce the contact resistance between the spraying area and the cores of the film capacitors, which has improved the quality of the capacitors.

Al/Zn metallized film has a better pressure resistance.

Al/Zn metallized film has a worse moisture resistance, easily oxidized.

2、Types of Metallized Layer:

Margin size(mm):1.0±0.5、1.5±0.5、2.0±0.5、2.5±0.5、3.0±0.5、4.0±0.5、5.0±0.5

Coating square resistance(Ω/□):Heavy-edge area:(3 ~ 5) ±1;Non heavy-edge area:(5 ~ 65) gradient

3、Cores:

4、 Roll Outer Diameter:

| 性能 Properties | 单位 Unit | 要求 Requirements |

| 密度Density | g/cm3 | 0.905±0.005 |

| 厚度 Thickness | µm | 3.8 ~ 15 |

| 抗拉强度 Tensile Strength | 纵向MD (MPa) | ≥100 |

| 断裂伸长率 Elongation at Break | 纵向MD (%) | 40 ~ 200 |

| 热收缩率 Heat Shrinkage | 纵向MD (%) | ≤5 ( 120°C, 10min) ( 120°C , 10 min ) |

| 介电强度 Break-dowm voltage | V/µm | ≥350 ( 23°C, DC ) |

| 介电损耗因数 Dissipation Factor | - | ≤4×10-4 (20℃,1KHz ) |

| RC值 | ΩF | ≥5×104 |

6、Packing:

7、 Storge:

1、Metallized film should be stored in its original package until its use with temperature 5 ~35℃and humidity less than 85%RH.

2、Metallized layer is easily oxidized when exposure to moisture. Therefore, the film should be used as soon as possible when opened.

3、The recommended temperature is 15 -25℃with humidity less than 60%RH after the package is open.

4、With original sealed package, and stored in the above mentioned conditions, the storage time can be as following:

Al metalized Film: 12 months from the delivered date

Al/Zn Alloy metalized Film: As Zn is relatively unstable, preservation period depends on the resistance of the film:

Less than 10 Ohms: 6 months (from delivery date)

10 Ohms to 15 Ohms: 3 months (from delivery date)

15 Ohms: 1months (from delivery date)